Need to know the basics about toolmaking?

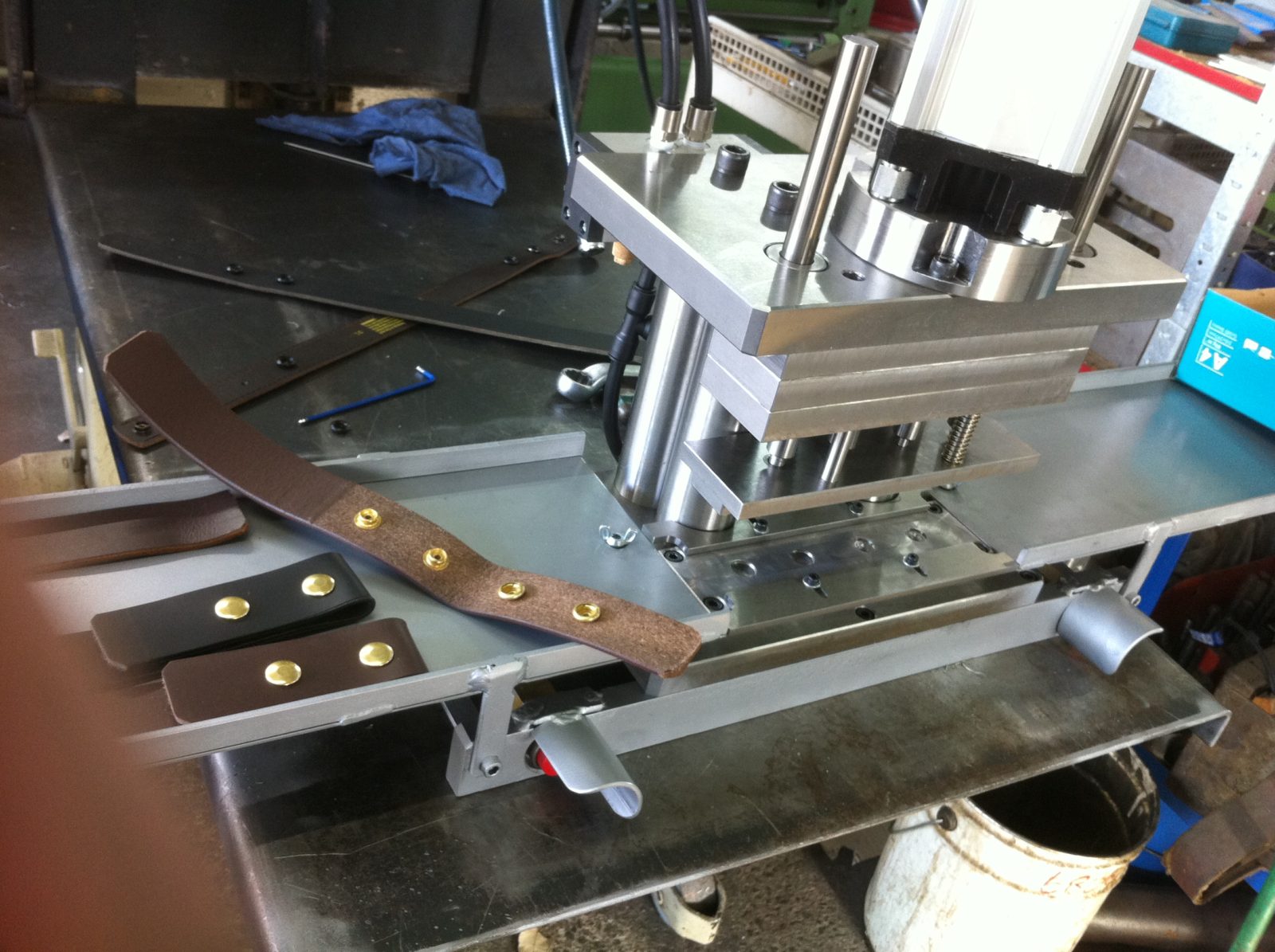

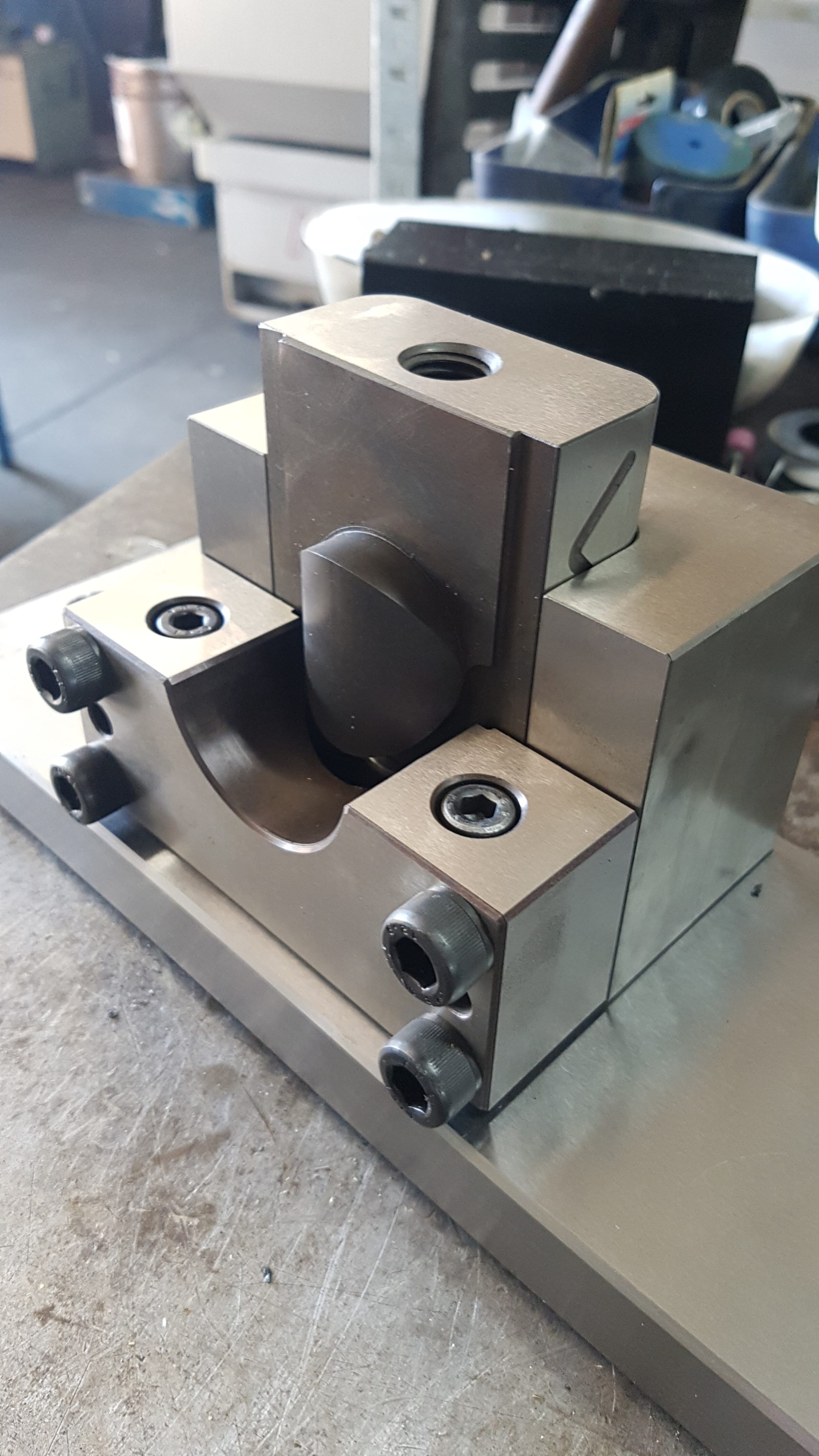

Toolmaking Services

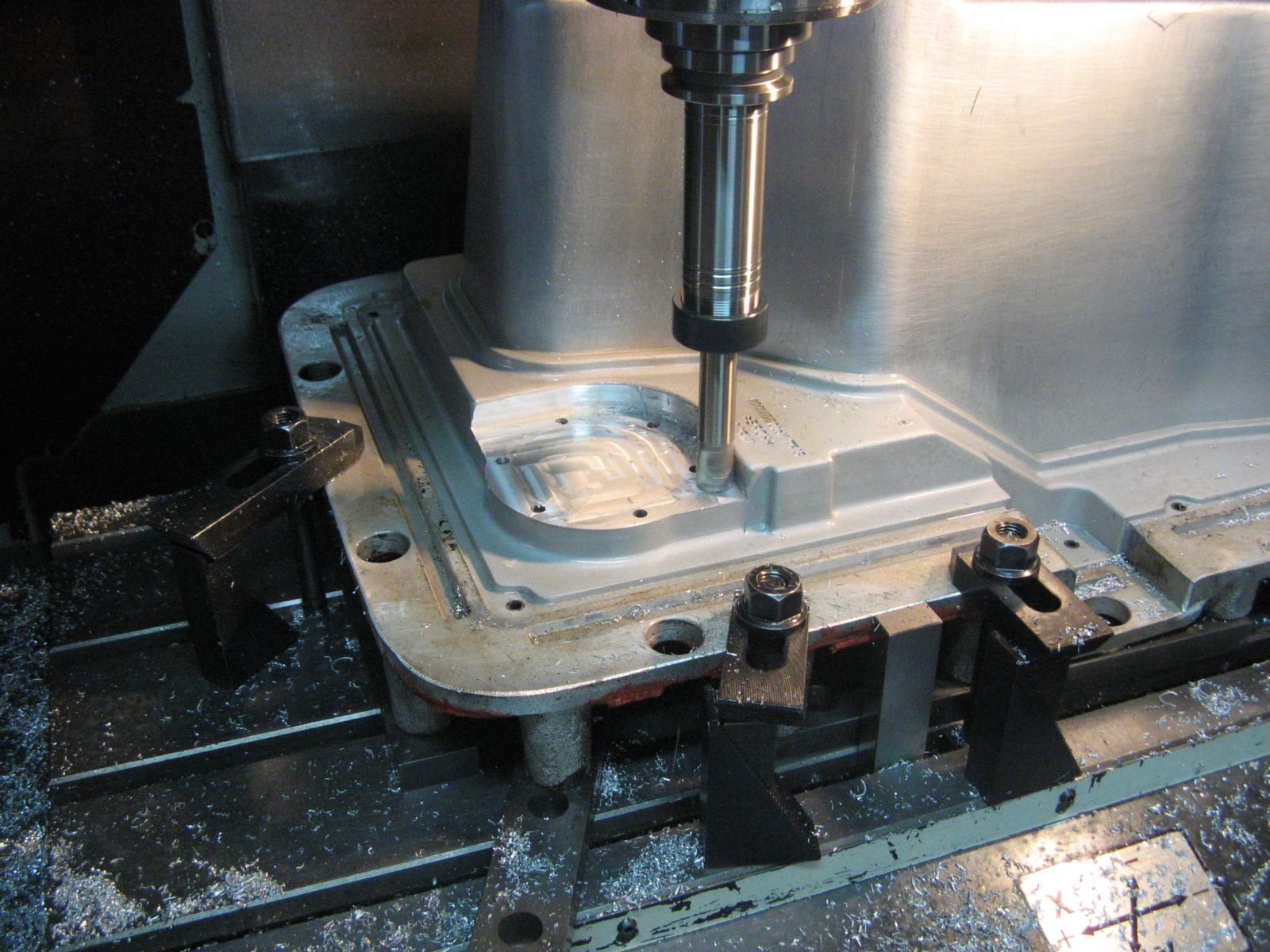

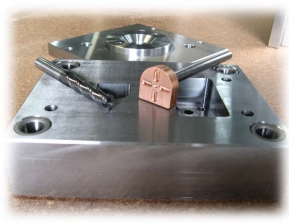

Toolmaking is the foundation of Ashden Industries. It’s where we began in 2002, and it remains central to the exceptional service and precision manufacturing we provide today.

With decades of experience in custom toolmaking, we understand the critical role high-quality tooling plays in successful plastic injection moulding. From concept to completion, we work closely with clients to develop tools that meet their production goals, budget, and product requirements.

Flexible & Supportive – Especially When It Counts

We know that the early stages of a new product launch can be stressful — with design changes, packaging, sales, and marketing all happening at once. That's why our team takes a collaborative, flexible, and proactive approach during this critical phase.

As a dedicated small business, we pride ourselves on being:

Accommodating and responsive to design changes

Focused on reducing delays and stress for our clients

Committed to supporting your product's success — because your success is ours too

We’ll go the extra mile to make things work — with minimal fuss and at a reasonable cost.

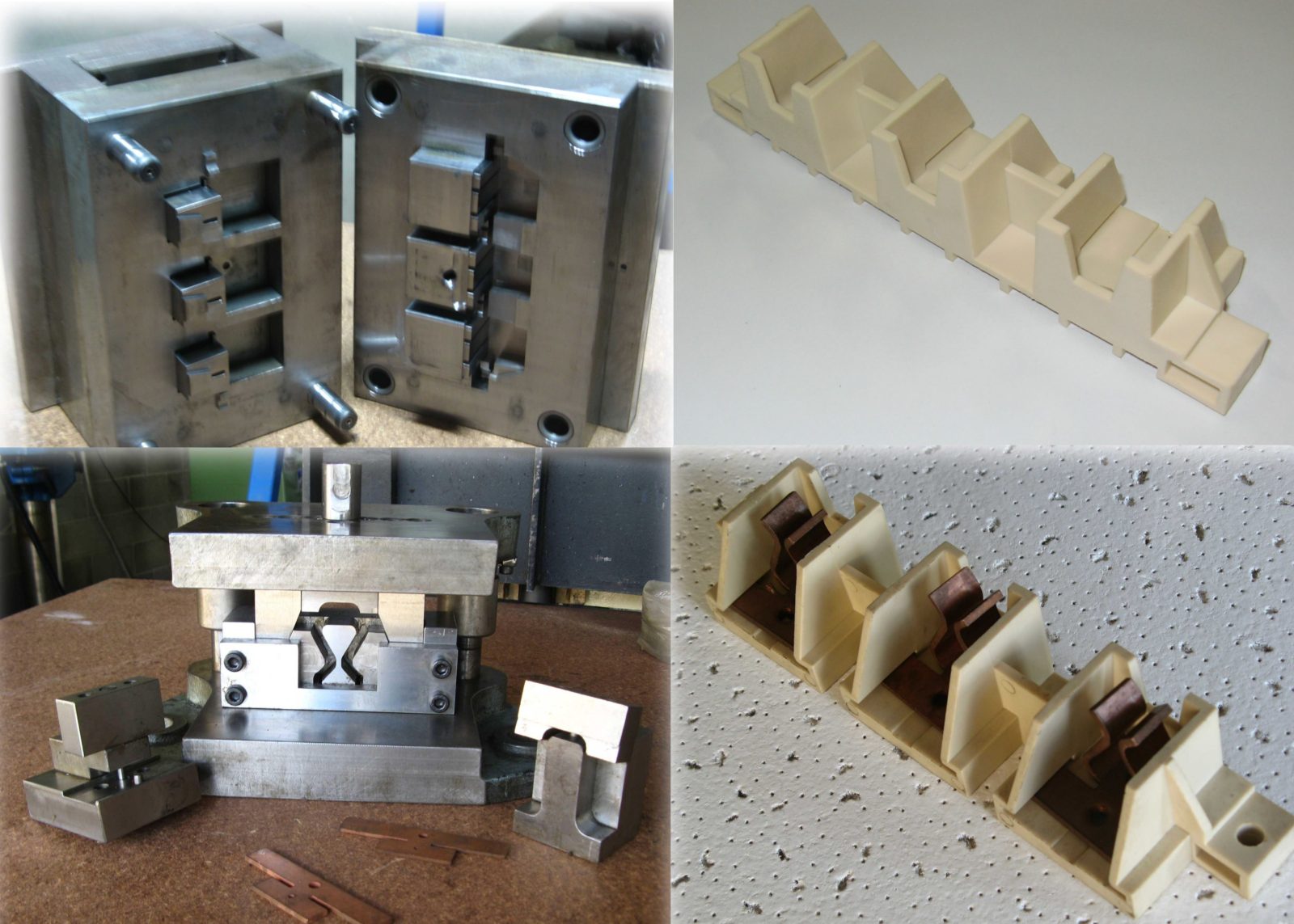

Mould Design Options Based on Production Volumes

We offer toolmaking solutions tailored to your required output — ensuring the best balance between upfront tool cost and per-part pricing.

Multi-cavity moulds with hardened tool steel inserts

Hot runner systems for efficient flow and reduced waste

Interchangeable parts for fast servicing

Higher initial cost, lowest cost-per-part

High-quality 4- or 8-cavity moulds

Hardened wear surfaces where needed

Hot runner or sub-gate systems

Balanced tool vs. part cost — tailored to your goals

Durable moulds using high-grade, non-hardened steels

Cost-effective gating (sub-gates or tab gates)

Ideal for low to mid-range production without sacrificing quality

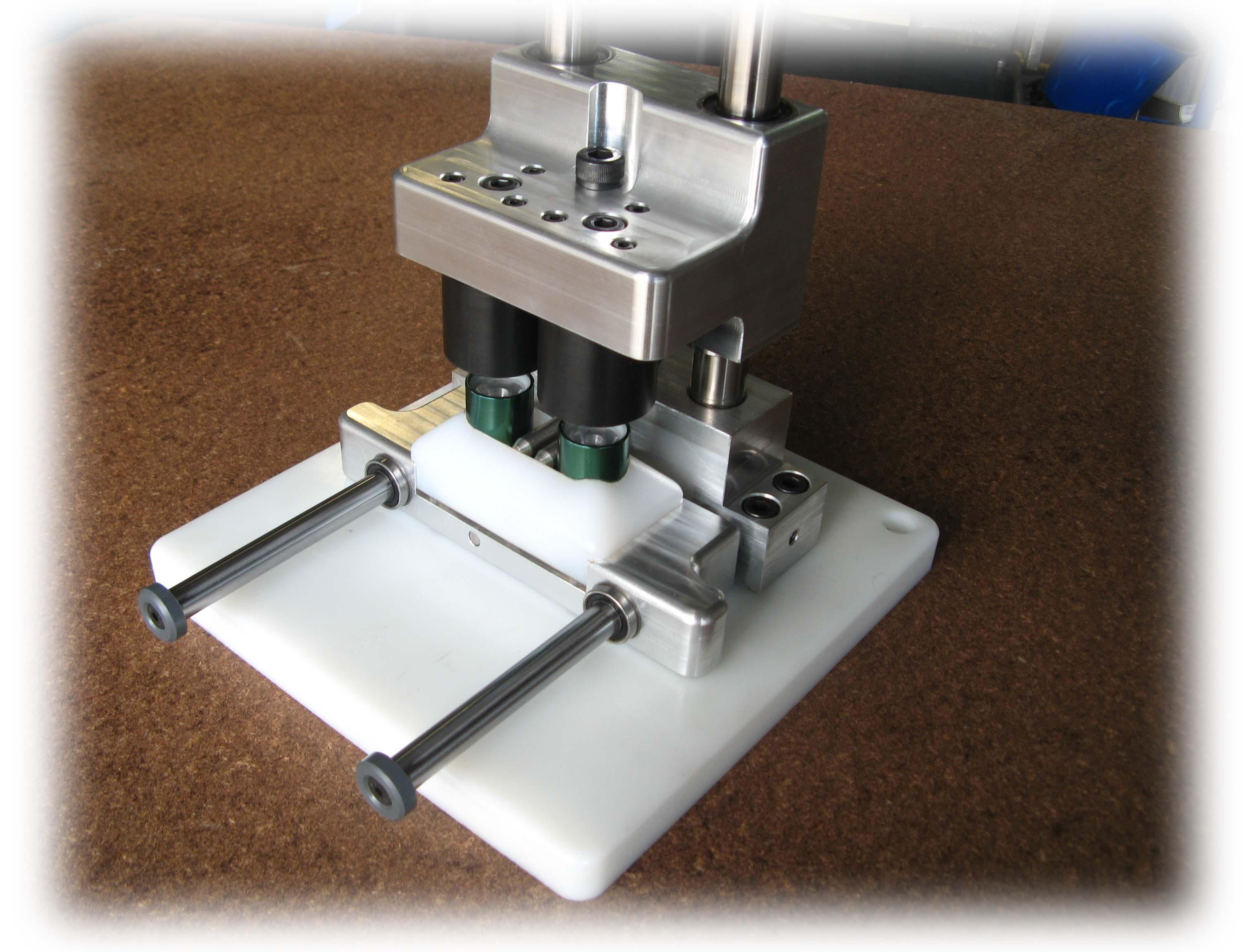

Simplified moulds with manual operations or minimal ejection systems

Secondary operations (e.g. drilling or machining holes/slots post-moulding)

Keeps mould cost low — higher part cost acceptable for small runs

On-Site Tool Maintenance & Modification

All moulds are maintained and modified in-house, ensuring fast turnaround and full quality control. We also provide ongoing support for any design updates or component changes throughout your product's lifecycle.

Ready to Build Your Mould?

Whether you're launching a new product, updating an existing tool, or exploring options for low- or high-volume production, Ashden Industries is ready to help.

Contact us today to discuss your toolmaking requirements.